- Car Audio

- Home Audio

- Marine Audio

- Powersports Audio

- Gear

- News & Events

- Support

- Find a Dealer

All-around performance in small enclosures at medium power levels.

W3v3 subwoofers offer phenomenal performance in medium power applications, without requiring a large enclosure.

This latest generation of W3 drivers benefits from a whole suite of advanced technologies originally developed for our flagship W7 subwoofers. A DMA-optimized motor system permits long, linear excursion capabilities, with minimal distortion and increased output, while multiple patented technologies enhance performance and reliability. These advances make these W3’s the best sounding, most reliable yet.

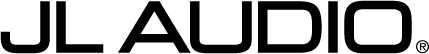

A mineral-filled, polypropylene, upper cone body with a metallic JL Audio logo medallion provides a simple, classy look. A removable (and customizable) mounting flange trim ring receives grille-mesh inserts (sold separately) directly, without the need for additional grille hardware.

All W3v3 subwoofers are built to exacting quality standards in our Miramar, Florida factory with global components and are offered in five sizes, ranging from 6.5-inch to 13.5-inch nominal diameters.

There’s no replacement for displacement!

Our 13.5-inch subwoofers deliver the most bang for your buck, every time!

13W3v3 can move 54% more air than a 12W3v3.

13W7AE can move 39% more air than a 12W7AE.

Amplifier Power Range

Recommended Amplifier Power Range (RMS) for One Subwoofer

Technology

JL Audio’s engineering department is at the forefront of research into fundamental loudspeaker behavior. We have developed proprietary analysis systems and invested heavily in state-of-the-art manufacturing and testing. This has borne numerous products widely considered as reference standards and has also resulted in many U.S. and International Patents issued for technologies that refine and extend the audio performance envelope.

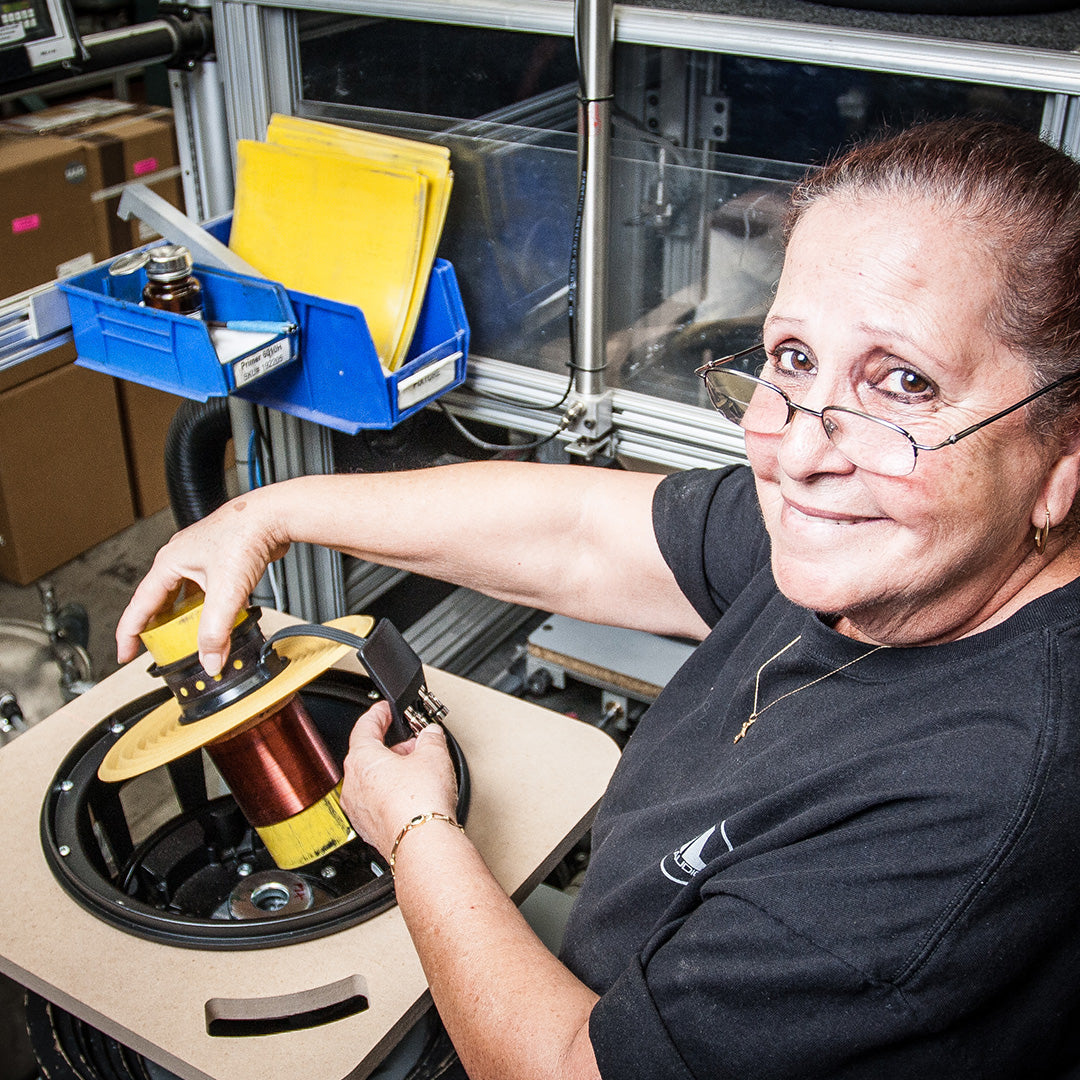

Built like no other.

Every W7AE, W6v3, TW5v2, TW3, TW1,& W3v3 subwoofer is built to exacting quality standards in our Miramar, Florida factory, with globally sourced components. All models are completely original designs from surround to back-plate (even the bolts and screws used in assembly have been purpose-designed and manufactured to our specifications).

A bit obsessive, perhaps, but so is the quest for the ultimate in audio reproduction...a goal that we pursue with passion, through research and without compromise.

Newsletter

Stay informed about new products and promotions.

Sign-up today!