Designed to excel in previously impossible spaces.

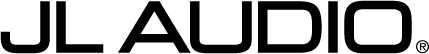

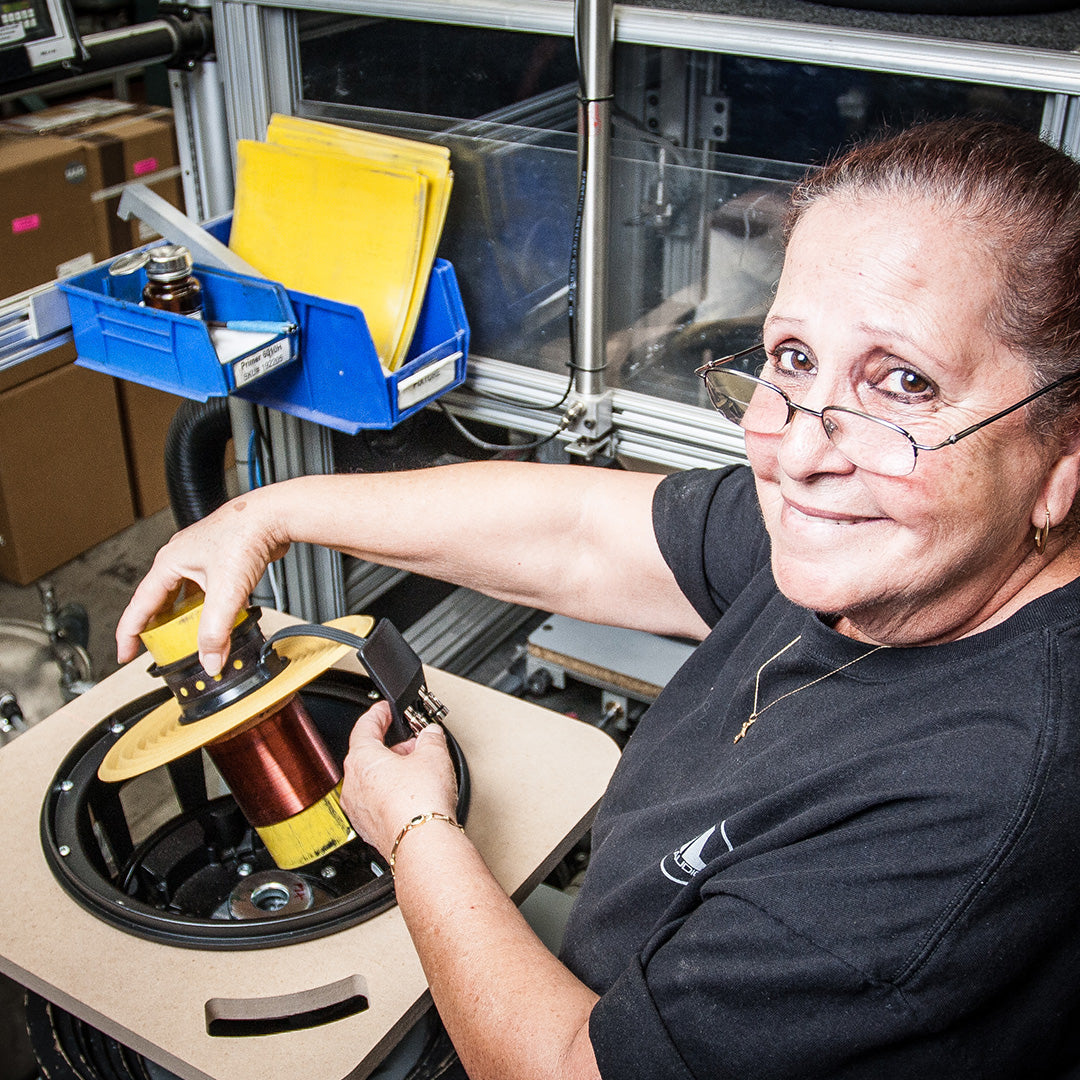

TW1 subwoofers are built in our Miramar, Florida factory and offer a powerful combination of shallow mounting depth, minimal frontal clearance and insanely small enclosure requirements. This makes them an outstanding choice for the tightest space applications.

Optimized for enclosures much smaller than any other JL Audio subwoofers, TW1’s never sound like a big woofer struggling in a tiny box... instead, they deliver all the rich, deep, controlled bass you have come to expect from a JL Audio subwoofer system.

JL Audio’s state-of-the-art Concentric Tube Suspension technology compresses mounting depth, using a “concentric tube” structure built into the injection-molded cone body, to deliver outstanding excursion capability and maximum performance potential.

TW1’s also employ a clever frame design that recesses the suspension attachment surface so that most of the forward excursion occurs within the frame’s dimensions. The result is a minimal frontal clearance of only 0.87 inches (22 mm), even with the supplied grille installed.

INSANELY SMALL ENCLOSURES

26% smaller than 10TW3!

10TW1 vs 10TW3 Enclosure Size Analysis

(recommended sealed volumes)

Technology

JL Audio’s engineering department is at the forefront of research into fundamental loudspeaker behavior. We have developed proprietary analysis systems and invested heavily in state-of-the-art manufacturing and testing. This has borne numerous products widely considered as reference standards and has also resulted in many U.S. and International Patents issued for technologies that refine and extend the audio performance envelope.

Built like no other.

Every W7AE, W6v3, TW5v2, TW3, TW1,& W3v3 subwoofer is built to exacting quality standards in our Miramar, Florida factory, with globally sourced components. All models are completely original designs from surround to back-plate (even the bolts and screws used in assembly have been purpose-designed and manufactured to our specifications).

A bit obsessive, perhaps, but so is the quest for the ultimate in audio reproduction...a goal that we pursue with passion, through research and without compromise.